In the fast-evolving landscape of construction management, the efficiency and organization of job sites are paramount. As we prepare for the year 2025, the utilization of job site storage containers is set to play a crucial role in optimizing project workflows. According to a report by the National Association of Home Builders, the construction industry has seen a 30% increase in the demand for innovative storage solutions over the past five years, highlighting the growing need for effective management of materials and equipment on site.

"Job site storage containers not only enhance site organization but also significantly reduce project delays caused by misplaced tools and materials," says industry expert John Patterson, a seasoned construction manager with over two decades of experience in operational efficiency. His insights underscore the importance of these containers in streamlining daily activities and ensuring that teams can access the right resources when they need them.

As we look ahead, the integration of advanced storage solutions will be indispensable for construction teams aiming to improve efficiency, safety, and productivity. The strategic use of job site storage containers will be pivotal in addressing the complexities of modern projects, ultimately contributing to successful outcomes and a more sustainable construction industry.

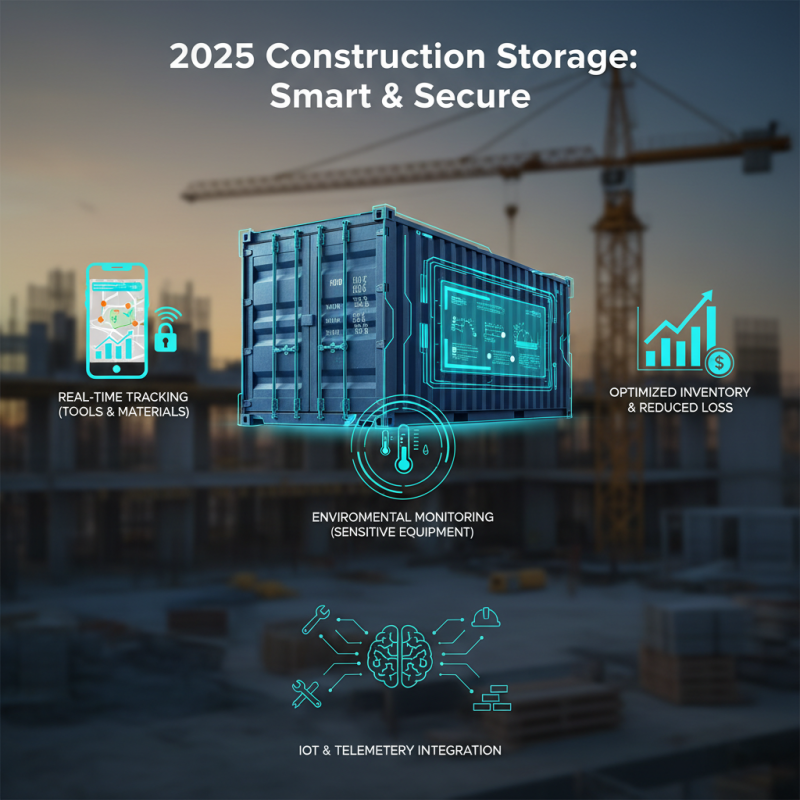

In 2025, the construction industry is expected to see a significant transformation in the way storage containers are utilized on job sites, primarily due to innovative features that enhance efficiency and security. Modern storage containers will be equipped with smart technology, including IoT (Internet of Things) capabilities, allowing for real-time tracking of tools and materials. This will enable project managers to monitor inventory levels instantly, reducing the risk of loss and ensuring that resources are optimally utilized. The integration of telemetry systems will also provide data on environmental conditions within the containers, helping to preserve sensitive equipment and materials.

Moreover, advancements in modular design are set to revolutionize how storage containers are used. These containers will be customizable to meet the specific needs of different construction projects, enabling seamless transitions between various sites. Features such as foldable sections and adjustable shelving will maximize space efficiency while maintaining accessibility. Enhanced security measures, including biometric locks and remote surveillance options, will protect valuable assets from theft and vandalism, allowing construction teams to focus on their work without concerns over tool safety. As a result, these innovative storage solutions will play a pivotal role in redefining effective construction management practices in the years to come.

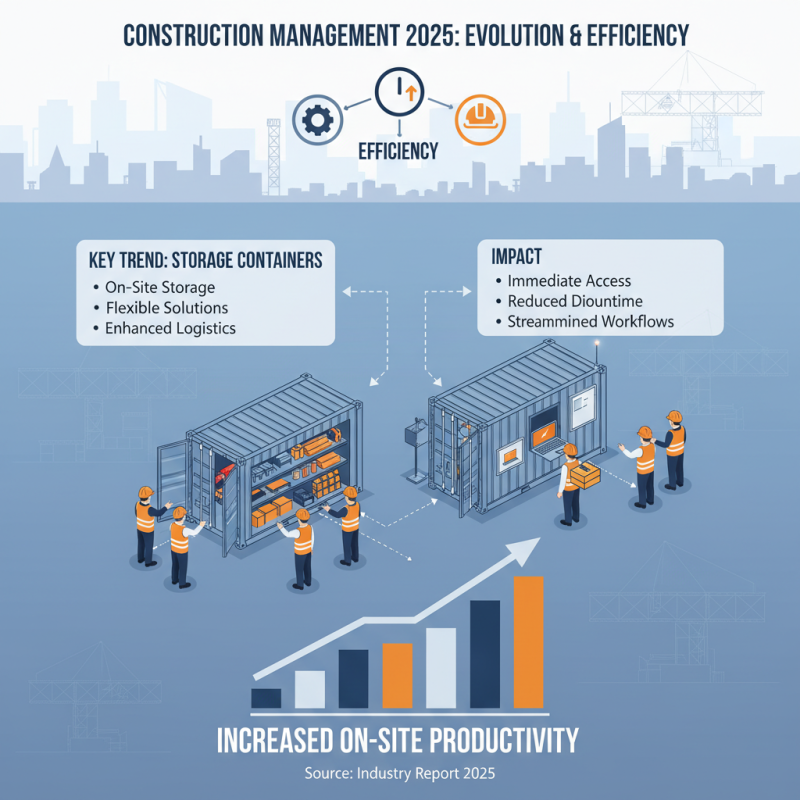

In the evolving landscape of construction management, storage containers have emerged as a pivotal resource for enhancing project efficiency. These versatile units not only provide secure storage for tools and materials but also facilitate easier organization and access on job sites. By utilizing storage containers, project managers can minimize delays caused by lost equipment and fragmented inventory, leading to streamlined workflows and improved productivity across the board.

Moreover, the flexibility of storage containers allows for adaptive project management. They can be strategically positioned at various points on a construction site, providing immediate access to necessary supplies and reducing travel time for workers. This strategic placement helps in maintaining a steady pace of work, as teams can quickly gather what they need without disruption. As construction sites often face unpredictable changes, having mobile storage solutions enables teams to respond effectively, keeping projects on track and within budget. The long-term benefits of using storage containers not only enhance operational efficiency but also contribute to a more organized and safer work environment.

Efficient organization of job site storage containers is crucial for maintaining productivity and ensuring safety in construction management. To achieve optimal organization, it's essential to implement a systematic approach. Begin by categorizing equipment and materials based on their function and frequency of use. Designating specific containers for specific items can minimize confusion and streamline retrieval processes. Clearly labeled containers not only expedite finding tools or materials but also enhance accountability among staff.

Another best practice for organizing storage containers involves strategic placement within the job site. Position containers closer to areas of high activity to reduce travel time and improve workflow. Utilizing stackable containers can optimize space efficiency, allowing for greater storage capacity without compromising accessibility. Regularly auditing the contents of these containers helps keep inventory accurate and reduces the risk of clutter. By fostering a disciplined storage environment, construction teams can enhance efficiency and maintain a safer worksite, ultimately leading to successful project outcomes.

| Container Type | Size (Cubic Feet) | Ideal Use Case | Access Method | Best Practices |

|---|---|---|---|---|

| Standard Storage Container | 320 | General Tools and Equipment | Lockable Doors | Label Contents Clearly |

| Refrigerated Container | 280 | Storage of Perishables | Temperature Control | Monitor Temperature Regularly |

| Tool Crib Container | 150 | Small Tools and Hardware | Shelves and Pegboards | Inventory Checklist |

| Office Container | 400 | On-site Administration | Wi-Fi and Electricity | Create Workstations |

| Dry Storage Container | 320 | Non-perishable Materials | Ventilation | Stack Items Properly |

In 2025, the construction industry is projected to witness a significant transformation in its management practices, particularly through the increasing utilization of storage containers. A recent report by MarketsandMarkets predicts that the global market for construction storage solutions will grow at a CAGR of 4.5%, highlighting the rising demand for efficient, secure, and mobile storage options. As construction projects become more complex and require better organization, choosing the right storage solutions is crucial for enhancing operational efficiency.

When comparing top brands offering construction storage solutions, several factors come into play. Key considerations include durability, capacity, accessibility, and security features. A study by the Construction Industry Institute emphasizes that proper storage can lead to a 20% reduction in on-site inventory shrinkage, further reinforcing the value of investing in high-quality storage containers. Additionally, a significant percentage of construction professionals—nearly 60% according to a recent survey—identify ease of access and mobility as essential features, allowing teams to quickly adapt to changing project needs.

Moreover, with sustainability becoming a focal point in construction practices, the use of eco-friendly materials in storage container production is increasingly favored. Reports from industry analysts indicate that companies prioritizing sustainable solutions see improved client satisfaction and project outcomes. As construction management continues to evolve, choosing the right storage container brand not only enhances productivity but also aligns with the industry's shift towards greater environmental responsibility.

As we look toward 2025, the landscape of construction management is evolving, driven by technological advancements and the pressing need for efficiency. One of the most significant trends is the increased utilization of storage containers. These containers are becoming essential not just for storage but also as flexible on-site solutions that enhance logistics and project management. By providing immediate access to materials and tools, construction teams can reduce downtime and streamline workflows, ultimately leading to increased productivity on site.

Moreover, the integration of smart technology into storage containers is revolutionizing their role in construction management. Features such as IoT sensors can monitor inventory levels and environmental conditions, ensuring that materials remain safe and accessible. This data-driven approach allows project managers to optimize resource allocation and predict needs more accurately, resulting in better planning and reduced waste. As industries push for sustainability, the use of eco-friendly materials in container construction and efficient energy management solutions will further align storage practices with modern environmental standards. This confluence of technology, efficiency, and sustainability is poised to redefine how construction projects are managed in the years to come.